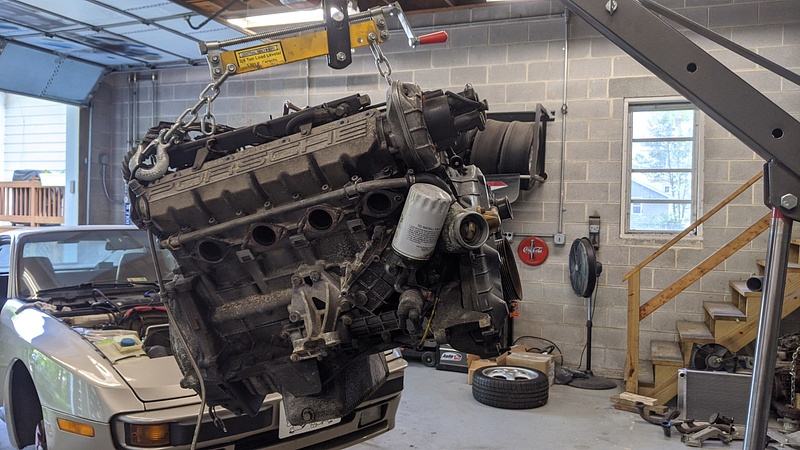

So, some deets on the motor:

There won't be too many pictures in this post, but I wanted to give a breakdown on this engine touching on the initial math and the changes made along the way. So, in the mid-90s, GM had two V8s that they put in their B-Body cars: the 5.7L LT1 and the 4.3L L99. Along the way, someone discovered that the L99's 3" stroke crank and 5.94" rods could be paired with the LT1's block and pistons to make a hydraulic roller 302. I believe Hot Rod or Chevy High Performance did an article on this back in the late 90s/early 00s. The one issue with this combination is that, while it would be cheap using factory parts, it was still using a flattop piston that set .025" below deck. Losing .48" of stroke meant that compression was going to suffer and needed to be made up elsewhere. In terms of the original 302, it retained the same 5.7" rod found in the 350, but had a large piston dome to raise compression to 11:1. So, I asked myself, "Why not bring the piston to the deck, if not slightly above the deck of the block?" I began playing with rod lengths and piston compression heights and finally settled on a 6.125" rod and a 1.400" piston. The longer rod would help slow piston speeds while increasing dwell time at top dead center, and the shallower piston would naturally reduce weight in the rotating assembly. This combination would effectively bring the piston to the 9.025" deck height. Assuming there would be a .005" cleanup pass of the deck's surface, the piston would be .005" out of the hole.

So, why the LT1 over a Gen 1 SBC? Well first and foremost, I had an LT1 block laying around that I had acquired for free. It is a 2-bolt main block, but with ARP studs, the webbing is actually stronger than the coveted 4-bolt blocks. Secondly, the LT1's intake manifold actually flows pretty damn well out of the gate, and even better with portwork. The intake also has a very low profile that fits underneath the stock 944 hood, and is set up for port fuel injection. Thirdly, the reverse-flow cooling design allows for more compression to be safely ran. The factory aluminum heads can be milled down to 52-51cc chambers, which would allow me to easily achieve 11:1 compression. Lastly, if I'm going to do an oddball setup in an oddball car, I might as well use the oddball generation of Chevy's small block.

My initial plan was to acquire some LT1 aluminum heads and send them out to be milled and ported. My desired compression ratio relied on the smaller chambers in conjunction with flattop pistons. However, scouring Facebook's Marketplace, I came across an ad selling some LT1 AFR heads and matching T&D rockers for a song. So, I scooped them up. They were older, pre-Eliminator castings that appeared to be in great condition. The one caveat was that they had 58cc chambers. After calling AFR, they told me that the decks could only be safely milled down to a 55cc chamber. This threw off the numbers and dropped compression more than I wanted. The difference would have to be made up with a dome.

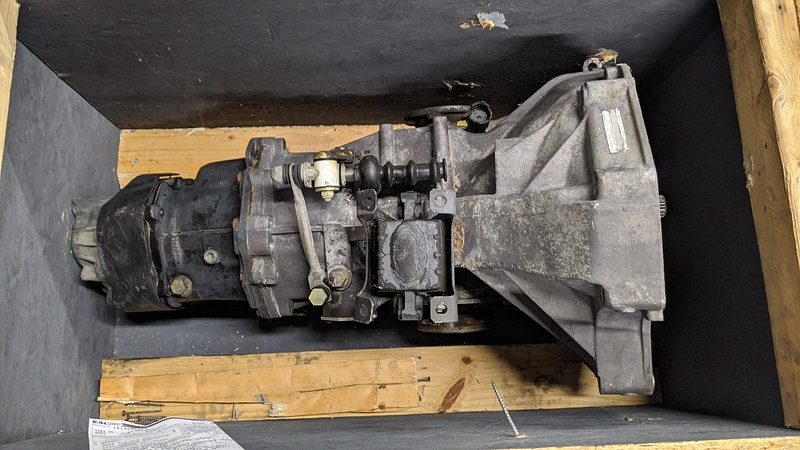

After acquiring the crank, rods, main studs, oil pump, and other miscellaneous items, I loaded up the parts and took them to the machine shop.

I then started placing calls to various camshaft manufacturers to work on the specs for the camshaft. I spoke with Cam Motion, Bullet, Howard, Erson, Isky, and Comp. Each manufacturer gave me their specs, and they wildly varied. Cam Motion specified one of their low-lash solid rollers at 224/228, 112 LSA. Bullet and Comp were in the mid-high 240s on duration. Erson went with a 230/238, 112 LSA. Isky decided on a 241/249, 112 LSA. Howard went with a 237/245, 112 LSA. Ultimately, I went with Howard. Typically, I tend to lean towards smaller camshafts, but I decided to give Howards spec a shot. The guy I spoke with, Eric, was very interested in my project, and even thanked me for having something that wasn't another 10:1 350 Chevelle. I had questions and he was responsive with the answers. The other companies weren't nearly as responsive, if not at all, and Bullet can piss right off. The guy I spoke to at Bullet felt it was a good plan to criticize the build altogether. I bought the cam, titanium retainers, springs, locks, and locators from Howards. I bought some Isky short travel lifters that are made by Johnson. The pushrods will most like come from Trend.

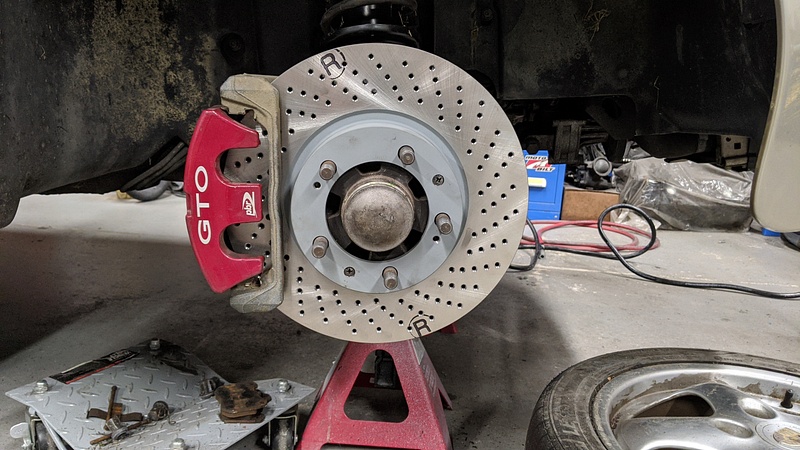

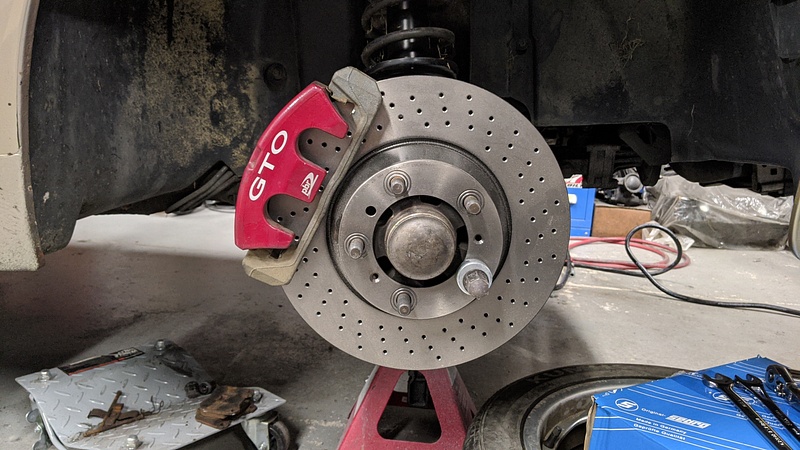

As anyone who has dealt with a machine shop before knows, these guys take their time. As it turned out, and a reason I hadn't ordered pistons yet, the block needed to be bored .030". This meant that I now needed 4.030" pistons, and my displacement is now closer to being a 305. The shop also felt it was best to leave the heads at 58cc instead of trying to cut them down to 55cc. This meant more piston dome was needed. So, a call was placed to Autotec, the same company that supplied pistons for my GTO's 404, and I had a set of 4.030", 1.400" height pistons with 7.6cc domes ordered.

Shortly after the pistons arrived, I received a call from the shop. The block's deck height had been previously cut down to 9.015, and after the shop made its finishing pass, the deck height was now 9.010. This effectively puts the piston .015" out of the hole. I was rather irritated with this news since my dimensions were made known to them at the start of the project, and I figured that deck height was verified when I was talking to them about piston options. Fortunately, Cometic makes a head gasket that is .056" thick, which keeps my quench at the desired .041". In the end, the compression went from 11:1 to 11.5:1. This is where the reverse-flow cooling comes in handy.

The final word of bad news occurred last week. I received a call about the cylinder heads. The machinist started cutting the seats and found that they were not concentric with the guides. Basically, he could fix them, but the price tag would be more than new heads. It's really the first time I got burned by a used purchase from the internet. It stung, but I'll get over it. More importantly, this put me in a bind, because most of the LT1 heads had a 55cc or smaller chamber, and since I had bought pistons with the 7.6cc dome, the smaller chambers were resulting in compressions over 12:1. While it is doable to run a 12:1 LT1 on pump gas, it wasn't something I really had a desire to tackle. After looking around some more, I found that Dart has a Pro1 casting that comes with 58cc chambers and 180cc runners. After placing a call to Dart, I was in luck. They ceased production on their LT1 line, but they had two pairs of 180cc Pro1 heads in stock. Now they only have one pair left. The second issue was the T&D shaft rockers that came with the AFRs. I wanted to use the shaft rockers for stability, but after calling T&D, they informed me that my rocker stands would not work, and since the rockers were older with no stamped part numbers, they couldn't verify if the rockers would work or not. I mulled it over, but ultimately decided to order a set of T&Ds to go with my Dart heads.

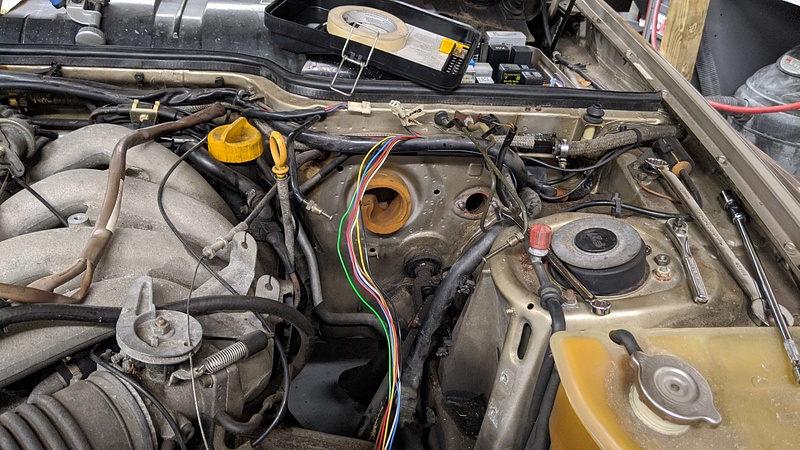

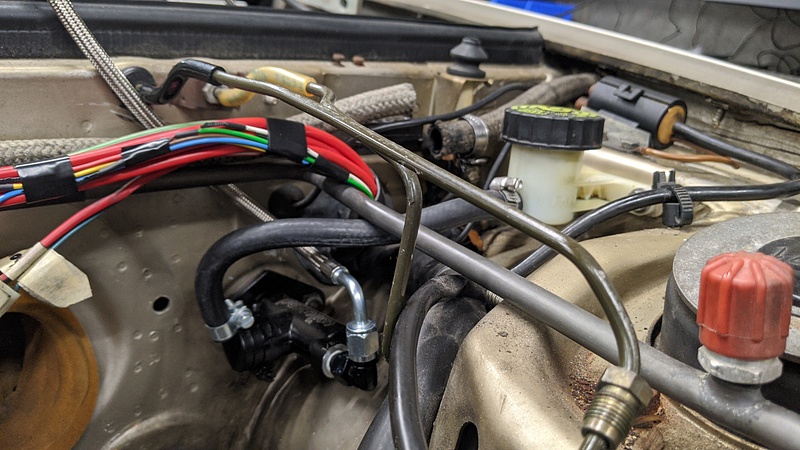

For the exhaust, I went to Sanderson. They offer a blockhugger with a 1 3/4" primary. The part number is CC-134. Space in the engine bay is tight, and these should still help the motor breathe.

So, in summation, here is where I stand with the motor:

Bore: 4.030"

Stroke: 3.000"

Rod Length: 6.125"

Rod: Scat Pro I-Beam

Piston Height: 1.400"

Dome Size: 7.6cc

Head Gasket Bore: 4.100"

Compressed Thickness: .056"

Camshaft: 237/245, .564/.563, 112 LSA/108 IC, Hydraulic Roller

Lifter: Isky Racing 2077HYRT, Silver Series HPX Short Travel

Cylinder Head: Dart Pro1, 180cc

Combustion Chamber: 58cc

work.

work.  to follow.

to follow.

Very good to know.

Very good to know.  AF. Best thread in here IMO.

AF. Best thread in here IMO. again!

again!

E30 thread of 2020

E30 thread of 2020